The most important feature of a flashlight is the structure of the LED socket which is serious for heat conduction and dissipation. Especially for high power LED, a well-structured LED socket can significantly reduce LED decline and guarantee a longer life.

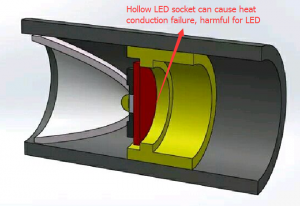

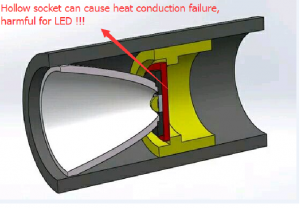

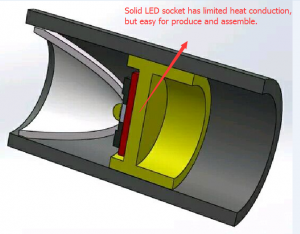

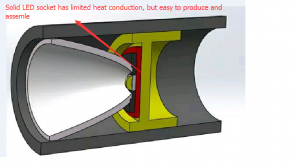

The following are the illustration for the Hollow LED socket, Solid LED socket, and our Integrative LED socket.

1. Hollow LED socket can cause heat conduction failure, really harmful for LED, really cheap!

2. Solid LED socket has limited heat conduction, but easy for produce and assemble, which is the best choice by most of brands to make profit.(Heat from LED→Solid Base→Outer Shell Head)

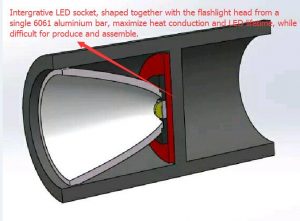

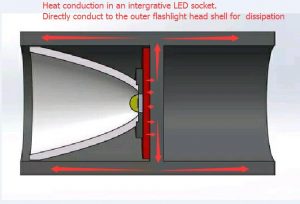

3. Integrative LED socket, shaped together with flashlight head from a single 6061 aluminum bar, which can maximize heat conduction. Heat transfer from LED directly to the thick base which is integrated with outer flashlight head.(Heat from LED→Thick Base Outer Shell Head)

Regardless of more difficulties to produce and assemble, we take Integrative LED socket for both spotlight series and floodlight series to make sure high luminance and guarantee a longer life.